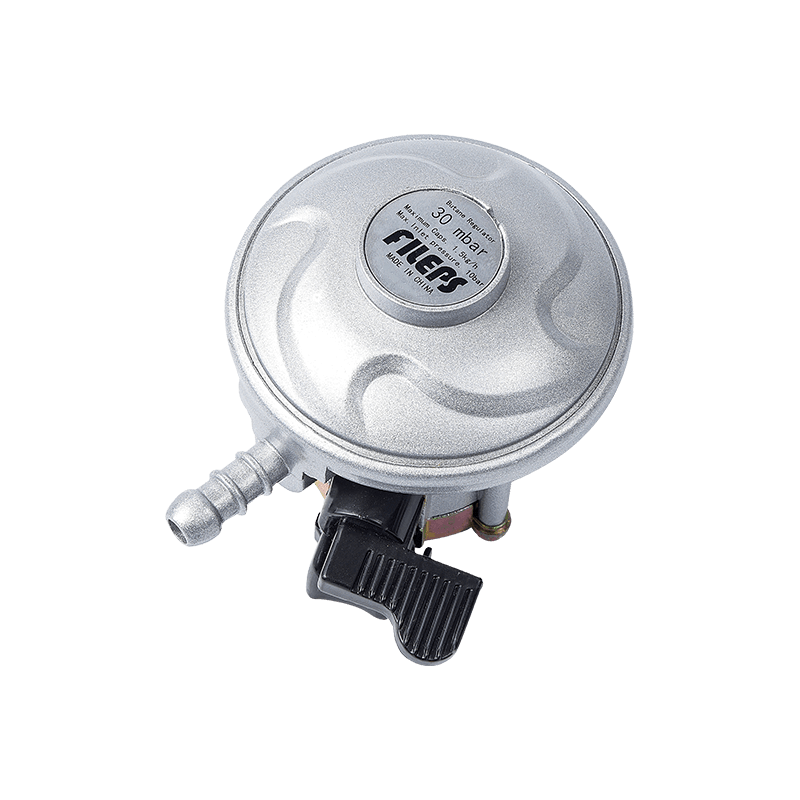

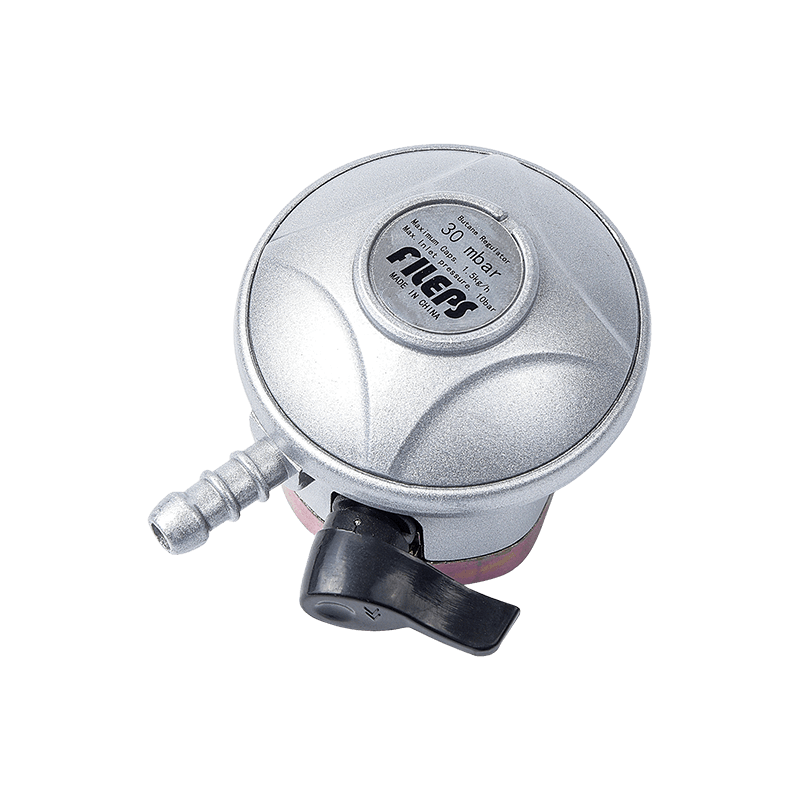

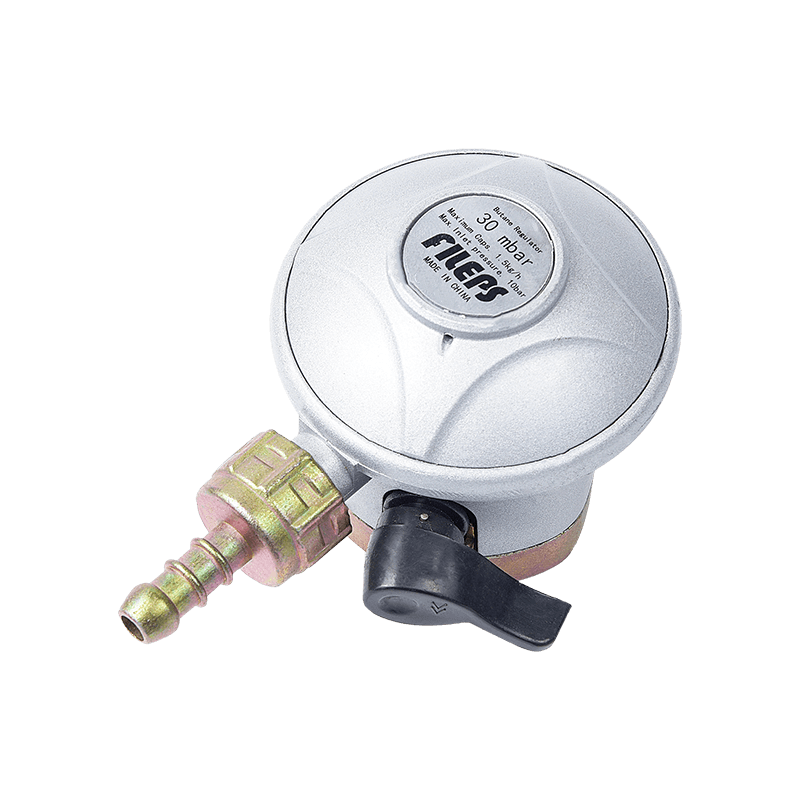

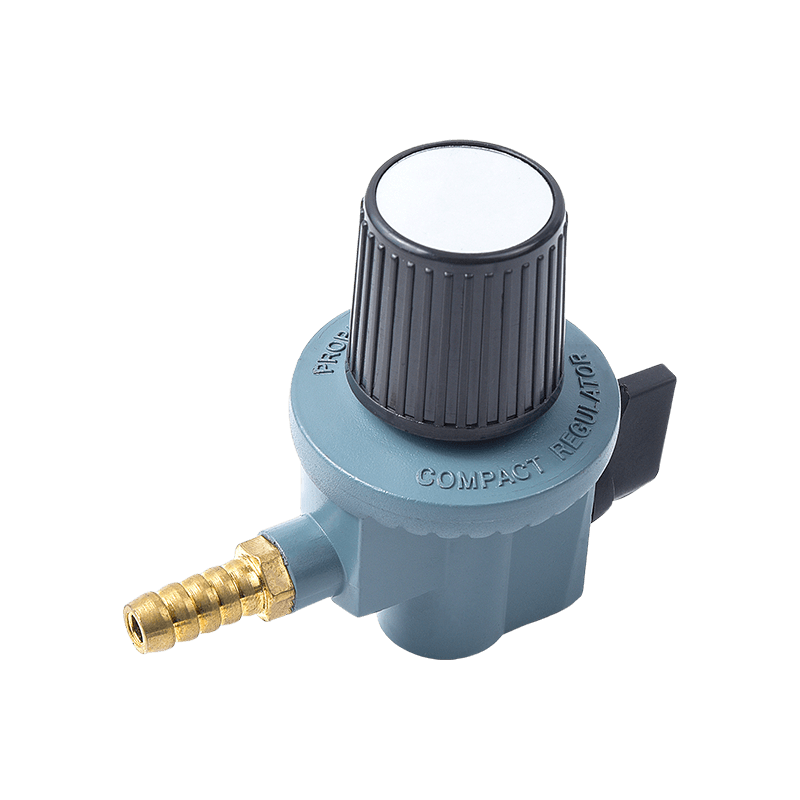

When installing the liquefied petroleum gas pressure reducing valve, you need to be cautious and formal. The specific installation requirements are as follows:

1. Before installing the liquefied petroleum gas pressure reducing valve, the pipeline needs to be pressure tested and purged to ensure the tightness and cleanliness of the pipeline.

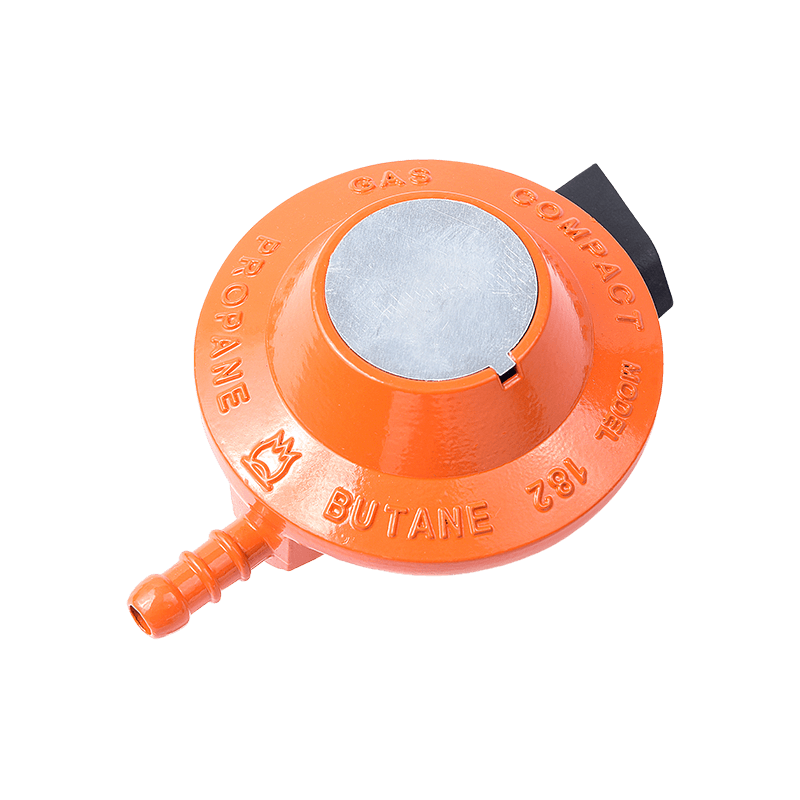

2. The liquefied petroleum gas pressure reducing valve should be installed horizontally and vertically on the pipeline. In addition, attention should be paid to ensure that the flow direction of the medium in the pipeline is consistent with the direction of the arrow shown on the valve body during installation.

3. Control ball valves should be installed on both sides of the liquefied petroleum gas pressure reducing valve, and bypass pipes should be installed for maintenance.

4. Pressure gauges should be installed on the high and low pressure pipelines of the liquefied petroleum gas pressure reducing valve to facilitate adjustment, and the pressure changes before and after the valve can be observed during operation.

5. A safety relief valve is installed on the pipeline to ensure the reliability and safety of the operation of the liquefied petroleum gas pressure reducing valve.

6. The indoor gas pipeline should be equipped with a gas leakage alarm device in the room to ensure that when the gas leakage is dangerous, the alarm can be reported and the danger can be eliminated in time.

7. In order to ensure safe use, after installing the liquefied petroleum gas pressure reducing valve, be sure to test the tightness. You can use a leak detector to detect or brush soap and detergent water at all pipe connections to check if there is any Air leak. If a pressure gauge is installed before and after the pressure reducing valve, you can turn off the air source and observe whether the pointer changes.

EN

EN English

English 中文简体

中文简体