1. Definition of gas source pressure

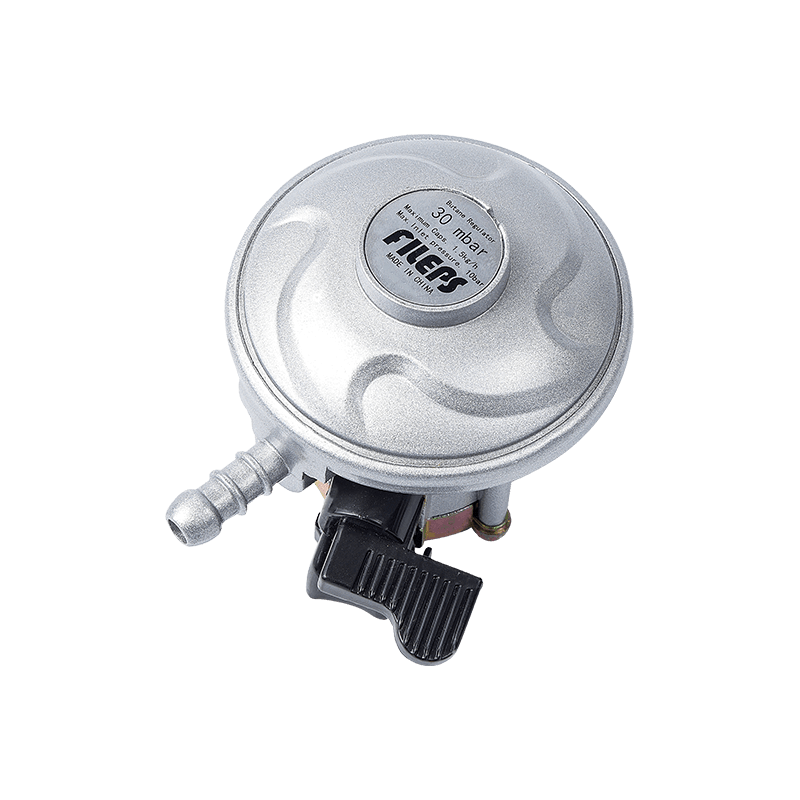

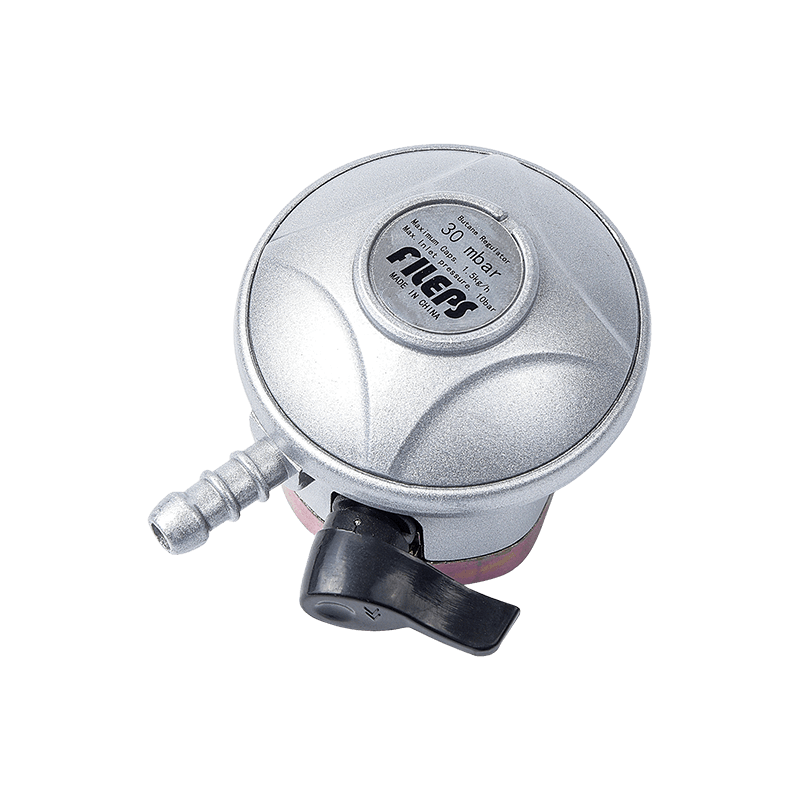

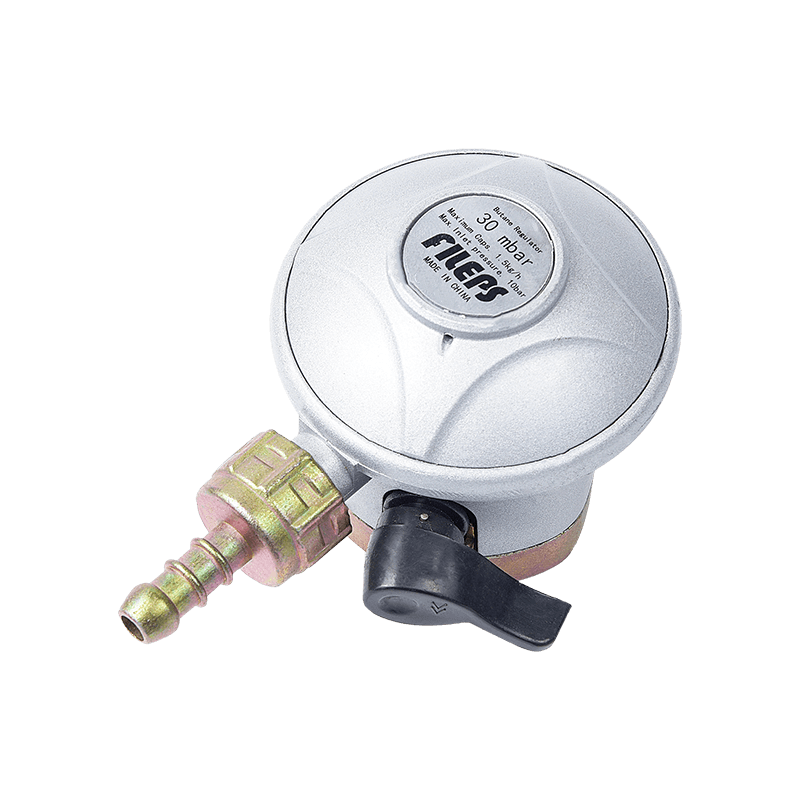

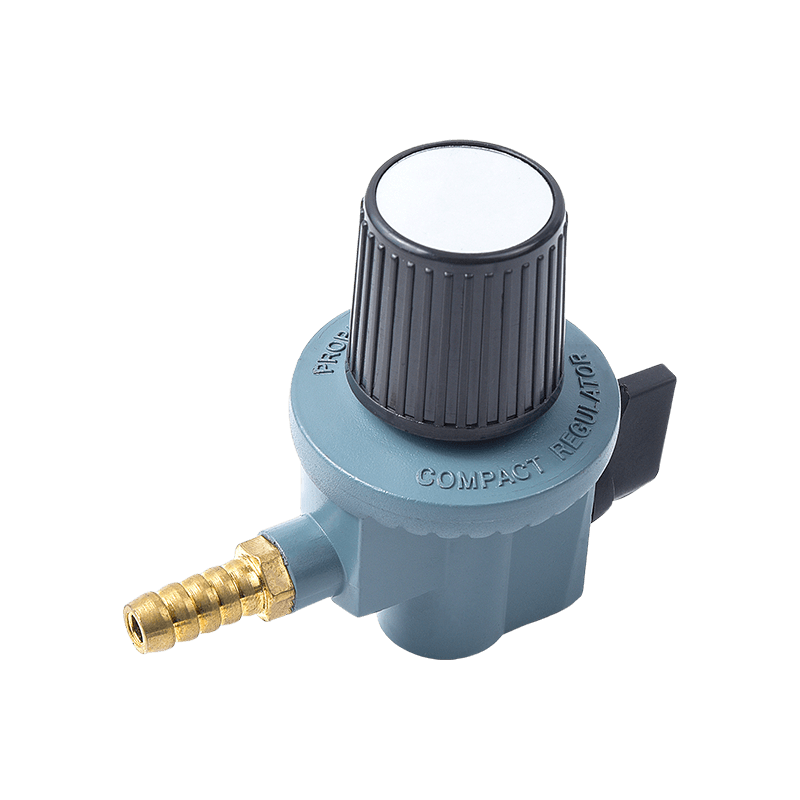

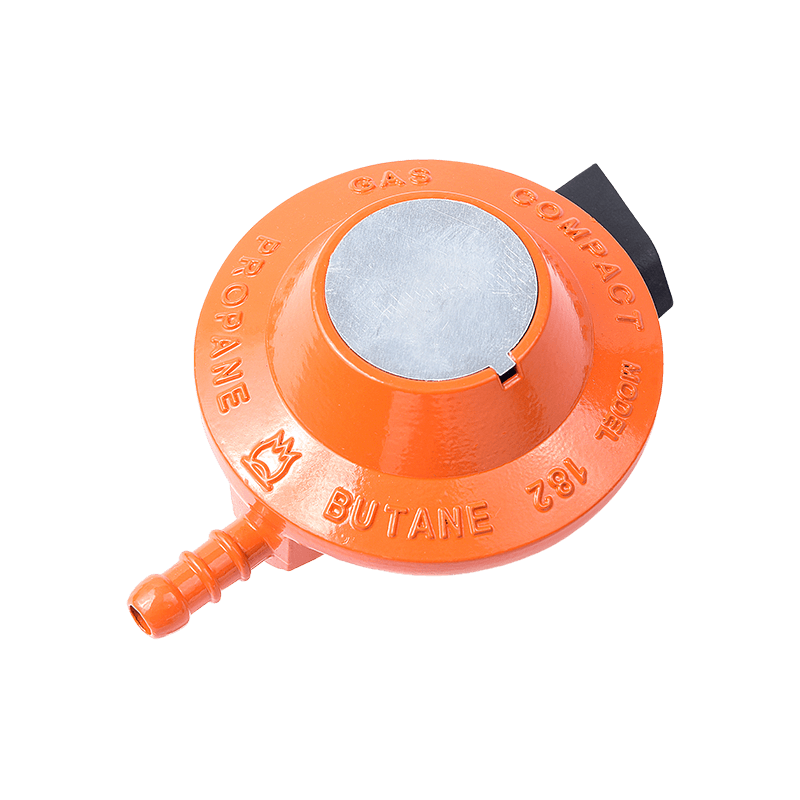

Gas source pressure refers to the pressure of gas in the gas supply system, usually expressed in kg/cm² or kPa. For Italy Cooking Cylinder LPG Gas Regulator, its inlet pressure range is 0.7-7 kg/cm². This range covers the pressure requirements of household and commercial gas sources, providing users with good applicability.

2. Effect of gas source pressure on outlet pressure

The outlet pressure of Italy Cooking Cylinder LPG Gas Regulator is 2.8±0.5 kPa. The level of gas source pressure directly determines the stability and efficiency of the outlet pressure.

Effect of low gas source pressure: When the gas source pressure is lower than 0.7 kg/cm², the regulator may not be able to reach the required outlet pressure, resulting in insufficient gas supply to the combustion appliance. This situation will cause incomplete combustion, resulting in unstable flames, affecting cooking results, and may increase the production of carbon monoxide, posing a threat to safety.

Effect of high gas source pressure: On the contrary, if the gas source pressure is too high, the regulator needs to make additional adjustments to control the outlet pressure. In cases, excessive inlet pressure may cause the regulator to overload, causing equipment damage or safety hazards.

III. Design adaptability of the regulator

The design of Italy Cooking Cylinder LPG Gas Regulator fully considers the changes in gas source pressure. It uses high-quality zinc alloy materials to ensure the stability and durability of the regulator under high pressure and high temperature environments. The precise internal structure can automatically adjust the outlet pressure according to the changes in gas source pressure to ensure that it is always maintained within the range of 2.8±0.5 kPa to meet the needs of different equipment.

IV. Monitoring and maintenance of gas source pressure

In order to ensure the good performance of Italy Cooking Cylinder LPG Gas Regulator, users should check the gas source pressure regularly. Here are some maintenance suggestions:

Use a pressure gauge: Install a pressure gauge in the gas source pipeline to monitor the gas source pressure in real time to ensure that it operates within the normal range.

Check the connection regularly: Make sure that the connection between the gas source pipeline and the regulator is firm and there is no leakage. Any gas leakage will cause the gas source pressure to drop, affecting the normal operation of the regulator.

Environmental adaptability: When installing the regulator, avoid placing it in a humid, high temperature or easily damaged environment to ensure its stable performance.

EN

EN English

English 中文简体

中文简体