1. The corrosion resistance advantages of zinc alloy materials

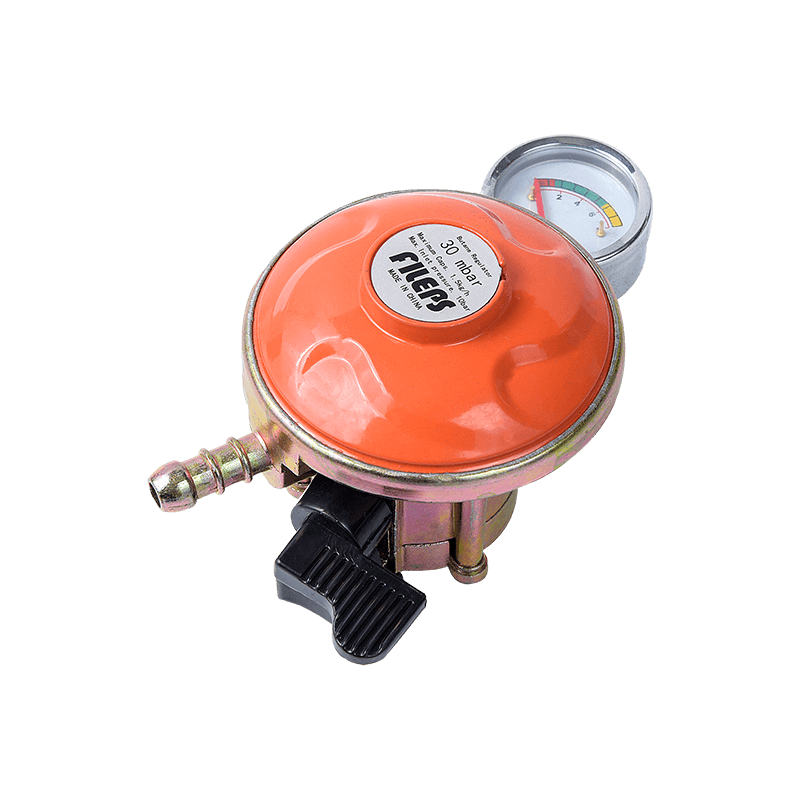

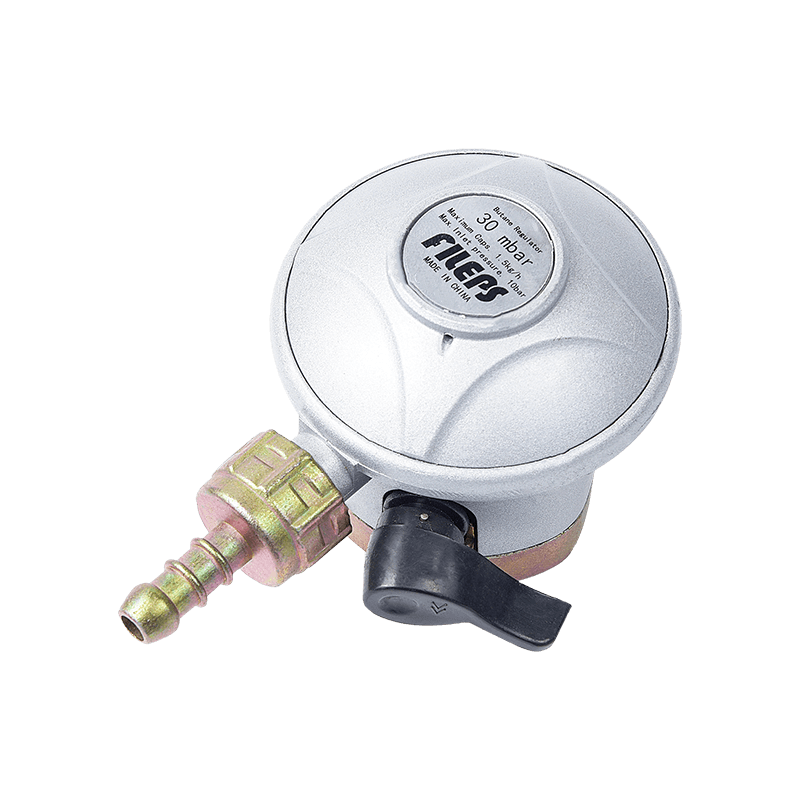

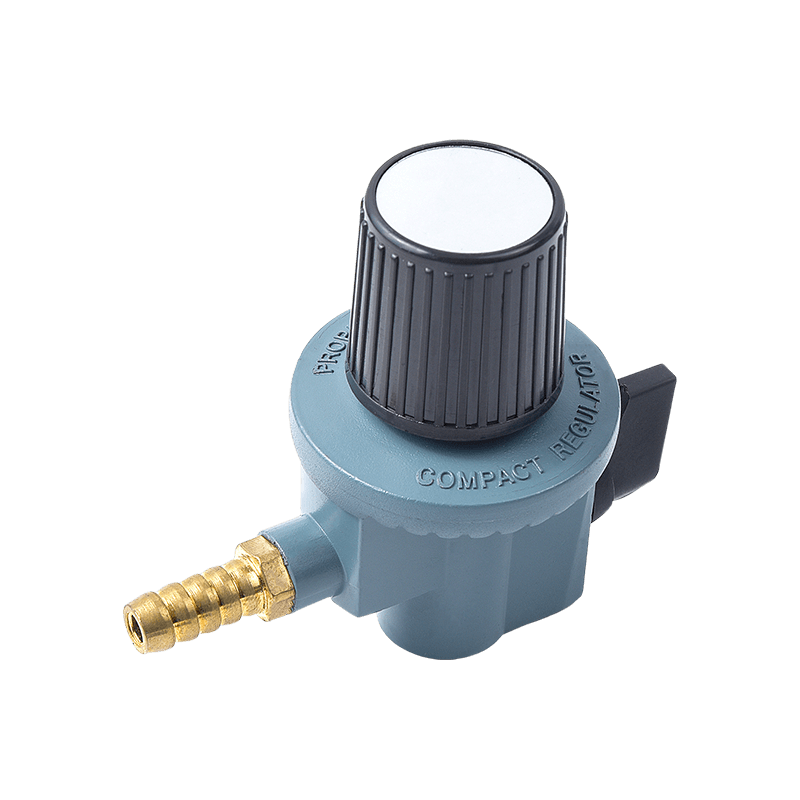

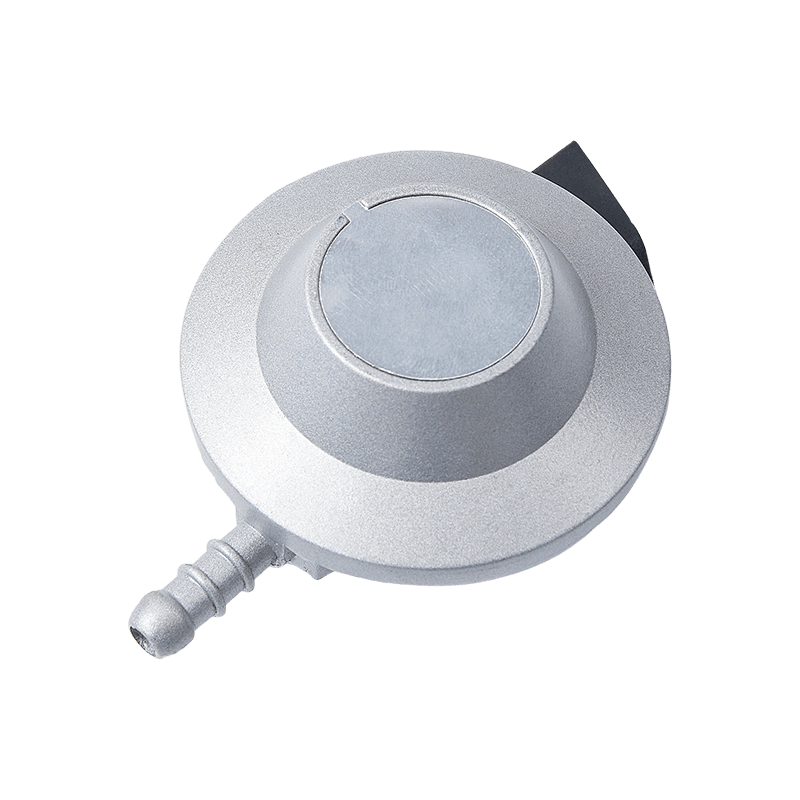

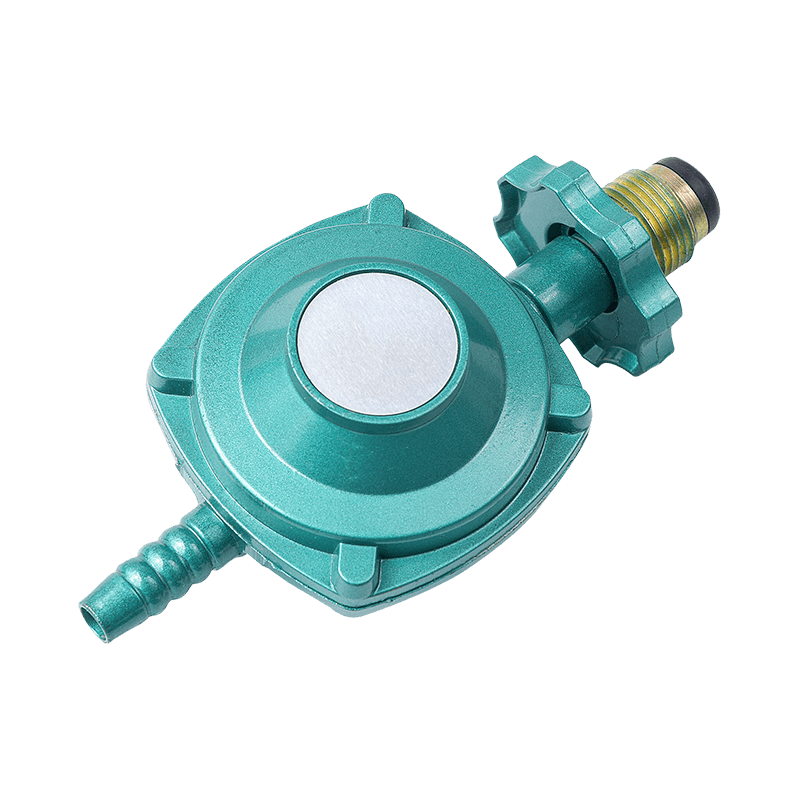

Nigeria 30mbar Cooking Butane LPG Gas Cylinder Regulator is made of zinc alloy, which has significant advantages when used in gas regulators. Zinc alloy is an alloy formed by adding zinc as a matrix and adding aluminum, copper and other metal elements. It has good corrosion resistance. Water vapor, oil fume and other corrosive substances are commonly found in the kitchen, which will corrode metal materials and thus affect the service life of the gas regulator.

Zinc alloy has oxidation resistance and can effectively resist the corrosion of moisture, salt and chemicals in the air. In a kitchen environment, regulators are exposed to moisture and high temperatures for a long time, and traditional materials are prone to rust or corrosion, leading to leakage or failure. However, zinc alloy can maintain the integrity of its surface and will not easily corrode. Therefore, the Nigeria 30mbar Cooking Butane LPG Gas Cylinder Regulator can maintain long-term stable performance during use and ensure the safety of kitchen gas.

2. The high temperature resistance of zinc alloy material improves safety

The kitchen is a place with frequent temperature fluctuations. High-temperature stoves, oil fumes, and steam released during cooking all pose certain challenges to equipment. For gas regulators, if the material does not have sufficient high temperature resistance, it is easy to age, deform or decline in performance in a long-term high temperature environment, thus causing safety hazards.

Zinc alloy material has good high temperature resistance and can withstand higher temperatures without structural changes. Nigeria 30mbar Cooking Butane LPG Gas Cylinder Regulator can still work stably in high temperature environments to prevent gas leakage or regulator failure caused by overheating. This makes it more reliable in high-temperature kitchen environments and can significantly extend the service life of the product.

3. It can still maintain stability even after being exposed to gas for a long time.

The gas regulator is in direct contact with liquefied petroleum gas (LPG). LPG itself is a chemically active gas. Long-term exposure to high temperatures, moisture and other corrosive substances may cause material aging or corrosion. The zinc alloy casing of the Nigeria 30mbar Cooking Butane LPG Gas Cylinder Regulator can effectively avoid this problem.

In addition, the internal structure and interface parts of the regulator also benefit from the application of zinc alloy materials, ensuring that no corrosive damage will occur during contact with gas. This corrosion resistance enables the Nigeria 30mbar Cooking Butane LPG Gas Cylinder Regulator to maintain its performance in various climatic conditions, providing stable gas output even in humid or salt spray environments, ensuring kitchen gas supply. security.

4. Zinc alloy material reduces maintenance frequency

Routine maintenance of kitchen equipment is an important means to ensure its long-term stable operation. If a gas regulator leaks or is damaged due to material corrosion, it often needs to be replaced or repaired frequently, which not only increases maintenance costs, but may also affect the normal use of the kitchen. The zinc alloy material of Nigeria 30mbar Cooking Butane LPG Gas Cylinder Regulator has corrosion resistance, which greatly reduces its maintenance requirements.

5. Improve overall service life

The corrosion resistance of the Nigeria 30mbar Cooking Butane LPG Gas Cylinder Regulator not only means a longer service life, but also means more safety and reliability during use. The overall design and material selection of a gas regulator directly affect its performance and lifespan, and the zinc alloy material enables this product to maintain efficient and stable working conditions in a variety of complex environments.

EN

EN English

English 中文简体

中文简体