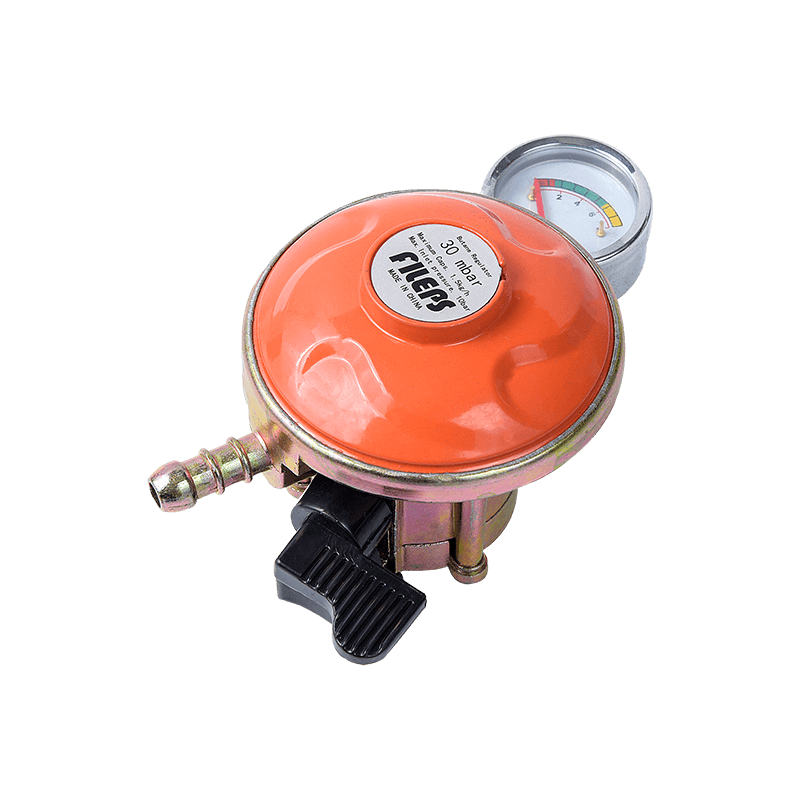

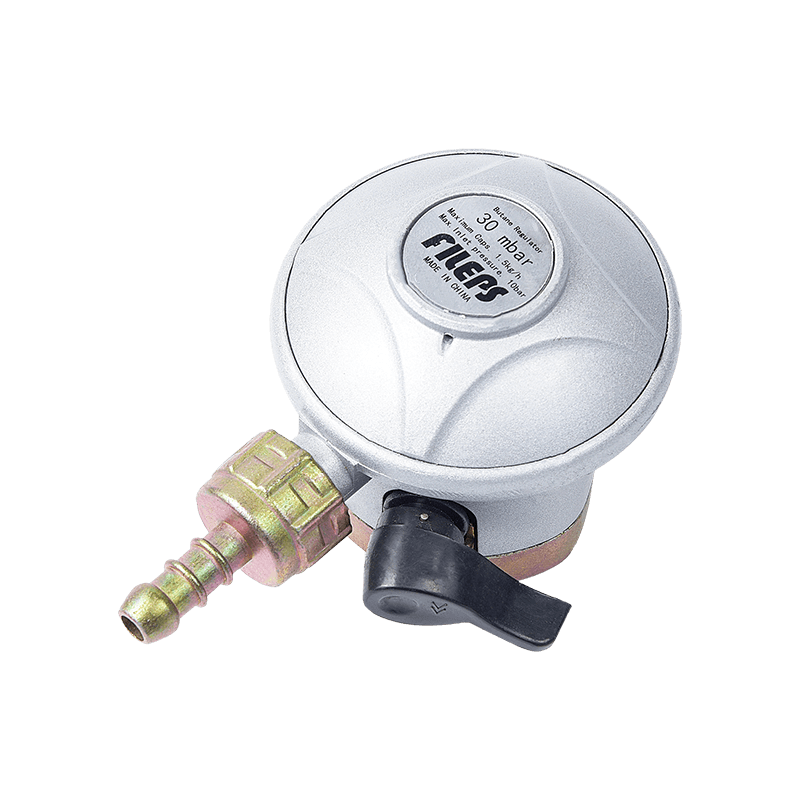

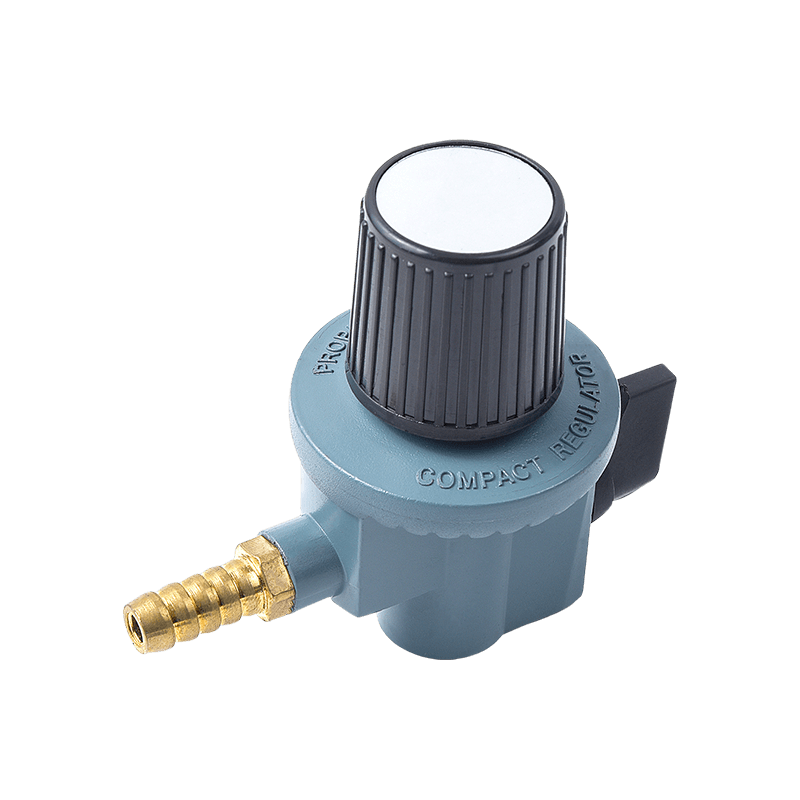

High Pressure Gas Regulators are indispensable components in modern industrial applications, laboratory research, and various other fields. Their primary function lies in adjusting the pressure of high-pressure gas sources to a desired, stable, and controllable low-pressure state, ensuring the safe and stable flow of gas during transportation and processing.

1. Ensuring Pressure Stability

Stable gas pressure is a prerequisite for ensuring a smooth industrial process or laboratory experiment. One of the primary functions of High Pressure Gas Regulator is to regulate unstable high-pressure gas to a desired stable low-pressure gas. Through internal adjustment mechanisms such as valves, springs, and pistons, High Pressure Gas Regulators can monitor and adjust gas pressure in real-time, preventing pressure fluctuations from affecting downstream equipment and process flows.

In numerous industrial and laboratory applications, precise control of gas pressure and flow is crucial. For instance, in chemical reactions, even minute changes in reaction conditions can impact the quality of the final product. High Pressure Gas Regulators, with their precise pressure regulation mechanisms, provide a stable and accurate gas supply, ensuring consistent reaction conditions, thus enhancing process precision and product consistency.

2. Enhancing Safety

High-pressure gases pose inherent hazards, including explosions and leaks. High Pressure Gas Regulators incorporate safety features into their design, such as overpressure relief valves and pressure relief devices. These features automatically release excess gas upon detecting abnormal pressure, preventing hazardous situations arising from excessive pressure. Additionally, regulators can promptly respond to gas leaks by shutting off gas flow, ensuring system safety.

3. Promoting Energy Efficiency

In gas transportation and processing, energy efficiency is a key focus for enterprises. High Pressure Gas Regulators, by optimizing gas pressure and flow, minimize energy losses and enhance system operational efficiency. For example, in gas compression and storage processes, using high-efficiency gas regulators can reduce compressor workload, lower energy consumption, and consequently decrease operating costs.

4. Extending Equipment Lifespan

Stable gas pressure not only ensures a smooth process flow but also extends equipment lifespan. High Pressure Gas Regulators by providing a stable gas supply, prevent damage and wear caused by pressure fluctuations to equipment. Especially in precision instruments and equipment, stable gas pressure can significantly reduce maintenance frequency, prolong equipment service life, and lower maintenance costs.

5. Versatility for Diverse Applications

High Pressure Gas Regulators are designed with flexibility to accommodate various gas types, including oxygen, nitrogen, argon, hydrogen, and more. In different industrial applications, distinct physical and chemical properties of gases necessitate adjustments and optimizations in the regulator based on the specific gas type. The versatility of high-pressure gas regulators allows them to function in diverse and complex process environments, meeting the demands of various industries.

6. Enhancing Production Efficiency

By providing stable gas pressure and flow, High Pressure Gas Regulators can significantly improve production process efficiency. Whether in continuous or intermittent production, regulators ensure a stable gas supply, minimizing production disruptions and efficiency losses caused by gas pressure fluctuations. Efficient gas regulation and supply not only enhance production efficiency but also boost overall production capacity.

EN

EN English

English 中文简体

中文简体