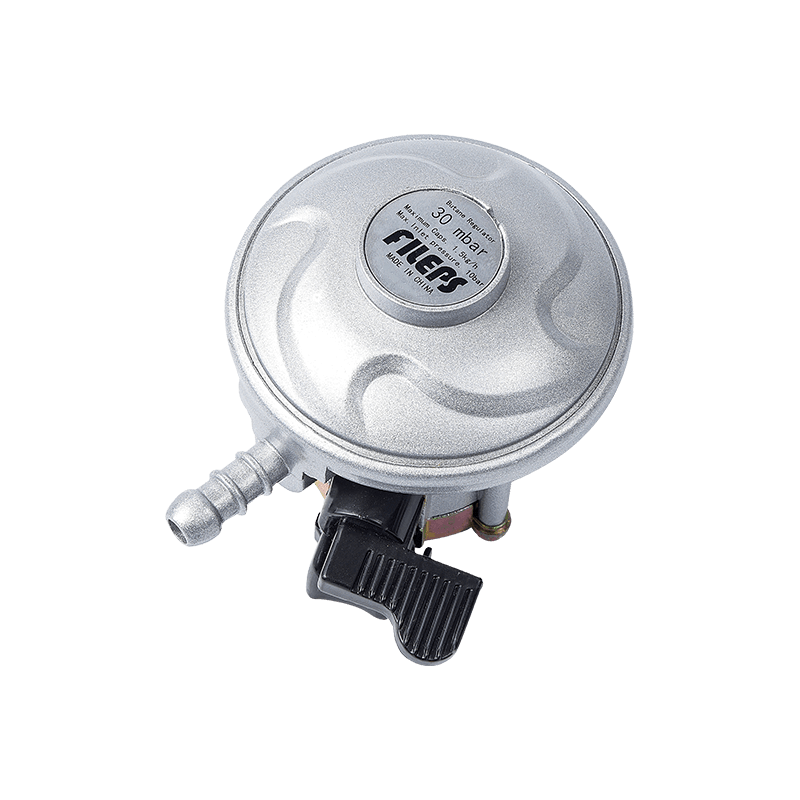

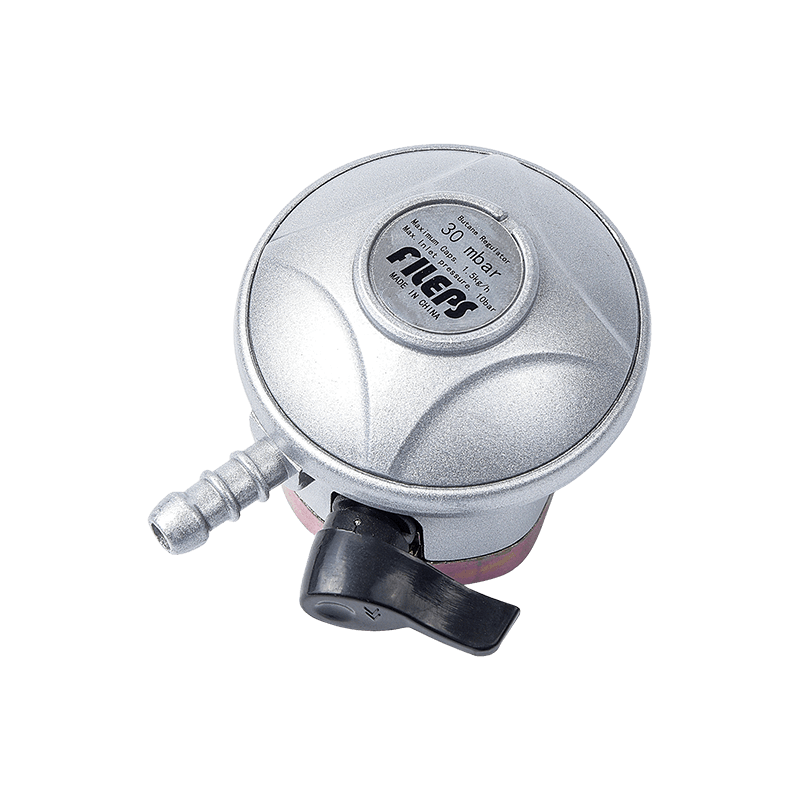

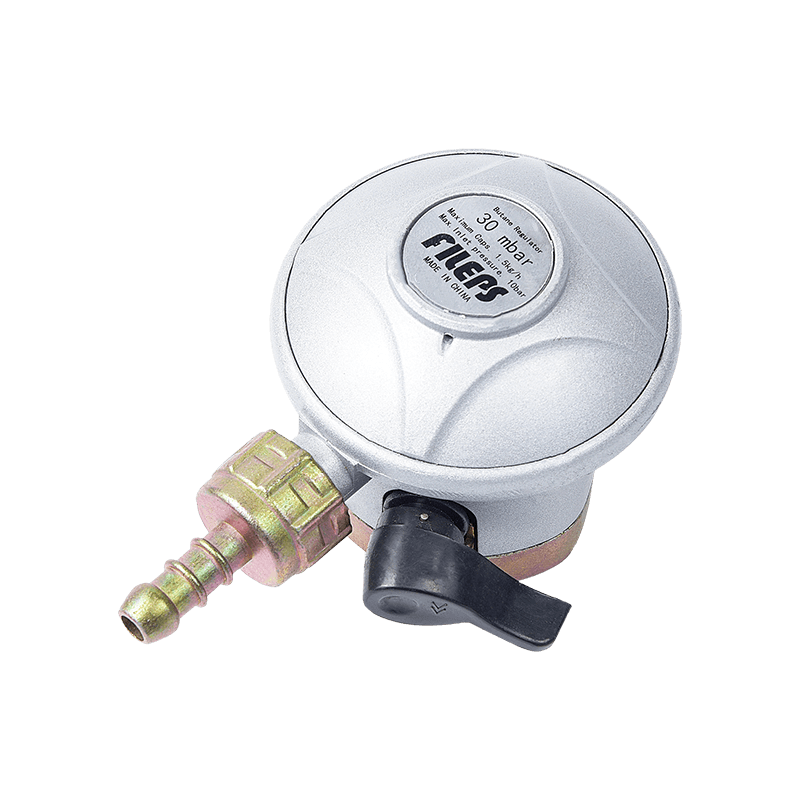

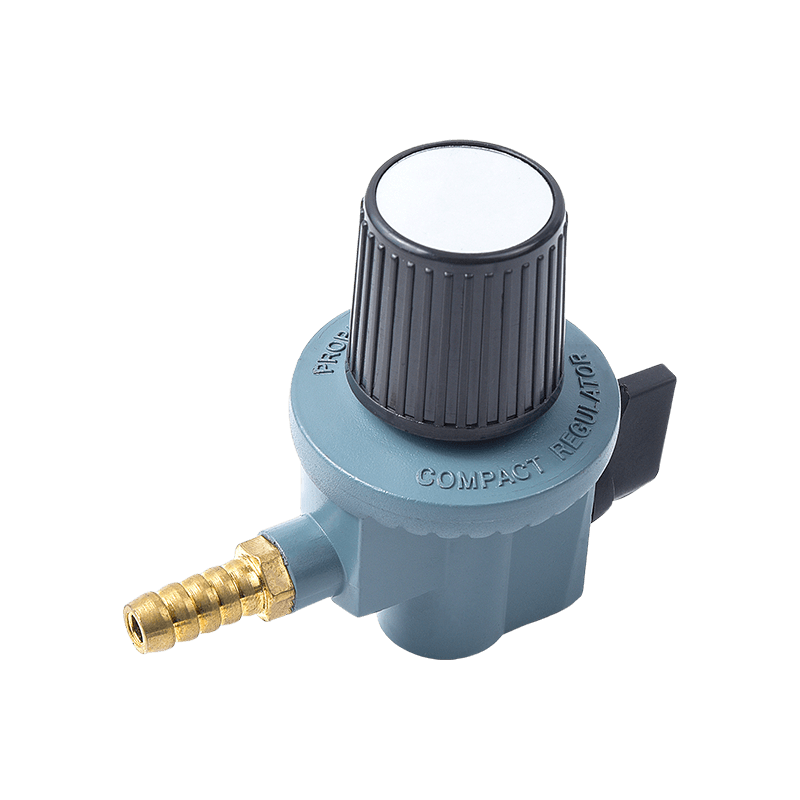

Low Pressure Gas Regulator plays a vital role in industrial and technological applications, and one of its main tasks is to ensure the stability of the output gas flow. Using proportional control technology is an effective way to achieve this goal.

First, it is crucial to understand the basic concepts of proportional control. Proportional control is a feedback control system that adjusts the output accordingly to changes in the input signal. In a Low Pressure Gas Regulator, the input signal usually comes from pressure sensors that continuously monitor the pressure of the input gas. When the input pressure changes, the sensor communicates this change to the control system.

The core task of the control system is to convert the input signal into an adjustment amount of the valve opening. This process relies on the set proportional gain, that is, the proportional relationship between input signal changes and output adjustment. Properly setting the proportional gain is critical as it determines how quickly and accurately the regulator responds to changes in input pressure.

Next, the control system calculates the valve opening that needs to be adjusted to maintain a stable output gas flow. For example, when the input pressure increases, the gas flow rate also increases. Failure to make adjustments may cause the output gas flow rate to exceed the predetermined range. At this time, the control system will appropriately reduce the valve opening according to the set proportional gain to return the output gas flow to the set value.

This feedback control mechanism enables the Low Pressure Gas Regulator to respond quickly and accurately to changes in input pressure, thereby maintaining the stability of the output gas flow. This stability is particularly important for many industrial processes. For example, in chemical production, reactors have very strict requirements on gas flow, and any fluctuations may affect reaction efficiency and product quality.

In addition, proportional control has the advantages of flexibility and adaptability. It can adjust proportional gain and control parameters according to different working conditions and application requirements, and adapt to various complex operating environments. For example, in applications that require frequent adjustments to gas flow, proportional control can respond and adjust quickly, avoiding the lag and instability problems that may occur with traditional control methods.

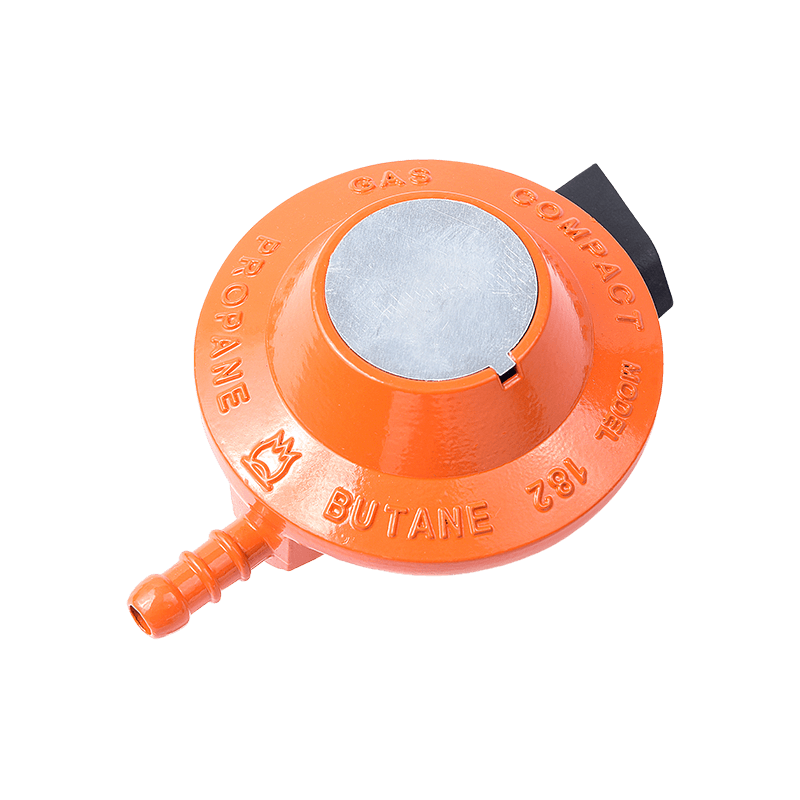

The design and material selection of the Low Pressure Gas Regulator also play an important role in ensuring stable output gas flow. High-quality regulators usually use corrosion-resistant materials and precision manufacturing processes to ensure long-term stable operation in various harsh environments. These design details further enhance the effect of proportional control, allowing the regulator to not only respond to changes in input pressure, but also maintain stable performance over long periods of use.

EN

EN English

English 中文简体

中文简体